Roll Fed Thermoformer:

* Brand: OMG

* Model: Elektra PVE 64

* Electrical: 480V/3Phase/60hz

* Control: 24 Volts AC

* Air Inlet Size: 1.0" NPT Female

* Working Air Pressure: 6 Bar 90 PSI

* Air Consumption Per/Cycle (approximate): 4 to 8 SCFM/Cycle

* Film Roll Holder Maximum Capacity: 1,000 Lbs.

* Film Roll Core Size: 3" or 6" (Customer to Specify)

* Typical Maximum Film Thickness: 0.060"

* Maximum Film Width: 33"

* Heating Power Upper Oven: 88 Ceramic Infra-Red Resistors, 43 KW

* Heating Power Lower Oven: 88 Ceramic Infra-Red Resistors, 43 KW

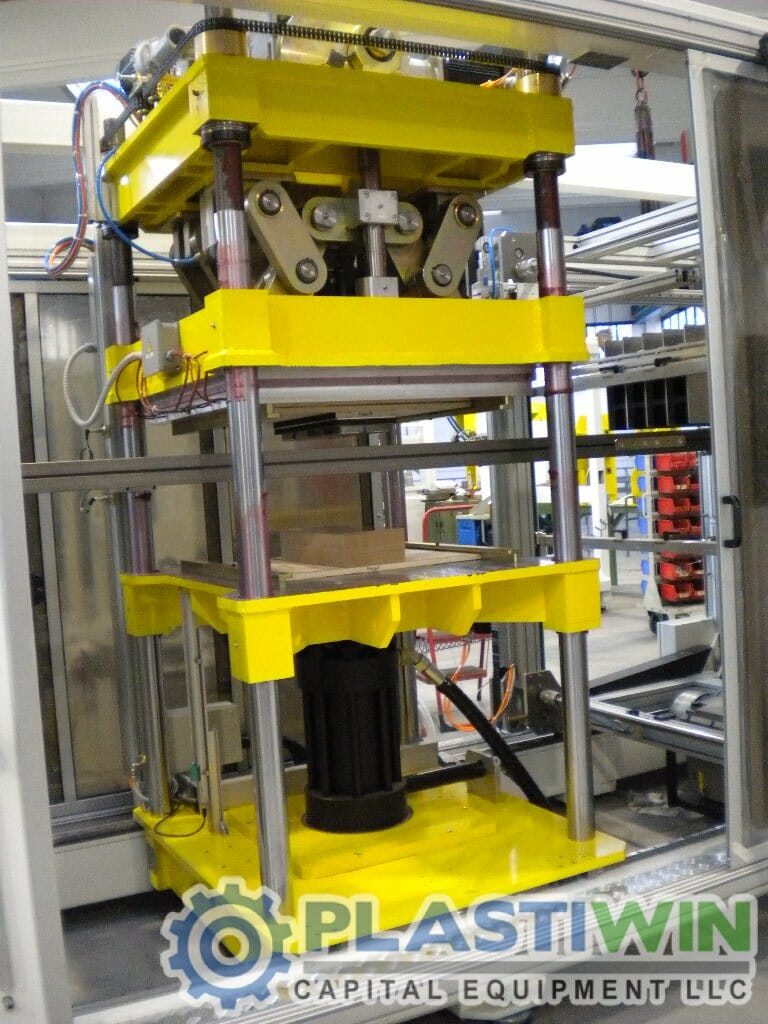

* Form Platen Acuation: Top/Bottom Servo Plug Drives, Toggles w/ Brushless Servomotor

* Maximum Form Press Closing Pressure: 40 Tons

* Vacuum System: Becker Electric, Positive Displacement, 160 M^3/H

* Vacuum Tank: 450 Liters

* Maximum Forming Area: 31.5" Wide x 31.5" Stroke

* Minimum Forming Area: 10" Wide x 8" Stroke

* Maximum Forming Height/Depth: 5.9" Top, 5.9" Bottom

* Trim Press Actuation: Toggles Top/Bottom w/ Brushless Servomoto

* Trim Press Closing Pressure: 110 Tons

* Finished Part Stacking: Up Stacking/Down Stacking, Brushless Servomotor

* Cycle Speed: Dry Cycle 50 CPM

* Approximate Dimensions: 564" x 137" x 108"

* Working Height: 60"

* Approximate Weight: 33,000 Lbs.

Standard Features:

* Programmable Logic Control (Omron)

* HMI Color Touch Screen Operator Interface (Omron)

* Main Power Disconnect with Lock Out

* Machine Cycle Reset Button

* Remote Emergency Stop Buttons

* Self-Loading Film Roll

* Infra-Red Heating System 3 Stage (Top and Bottom)

* Individual Heater Element Controllers (Zoned, Top and Bottom)

* Double Row Pierce Chain Film Advance with Water-Cooling System

* Servo Motor Driven Chain/Film Advance

* Servo Motor Driven Upper and Lower Mold Platen

* Servo Motor Driven Top/Bottom Plug Drives

* Pressure/Vacuum Forming Capacity (Top and Bottom)

* Four Post Servo Toggle Trim Station

* Motor Driven Die Adjustments (X/Y/Z)

* Servo Motor Driven Up/Down Stacking System w/ Count and Push-Off Feature

* Horizontal Take Out Conveyor

* Automatic Scrap Winder

* Steel Components Polyurethane Coated

** Comes with Full 1 Year Factory Warranty **

** 2010 Model with 20,000 Cycles **