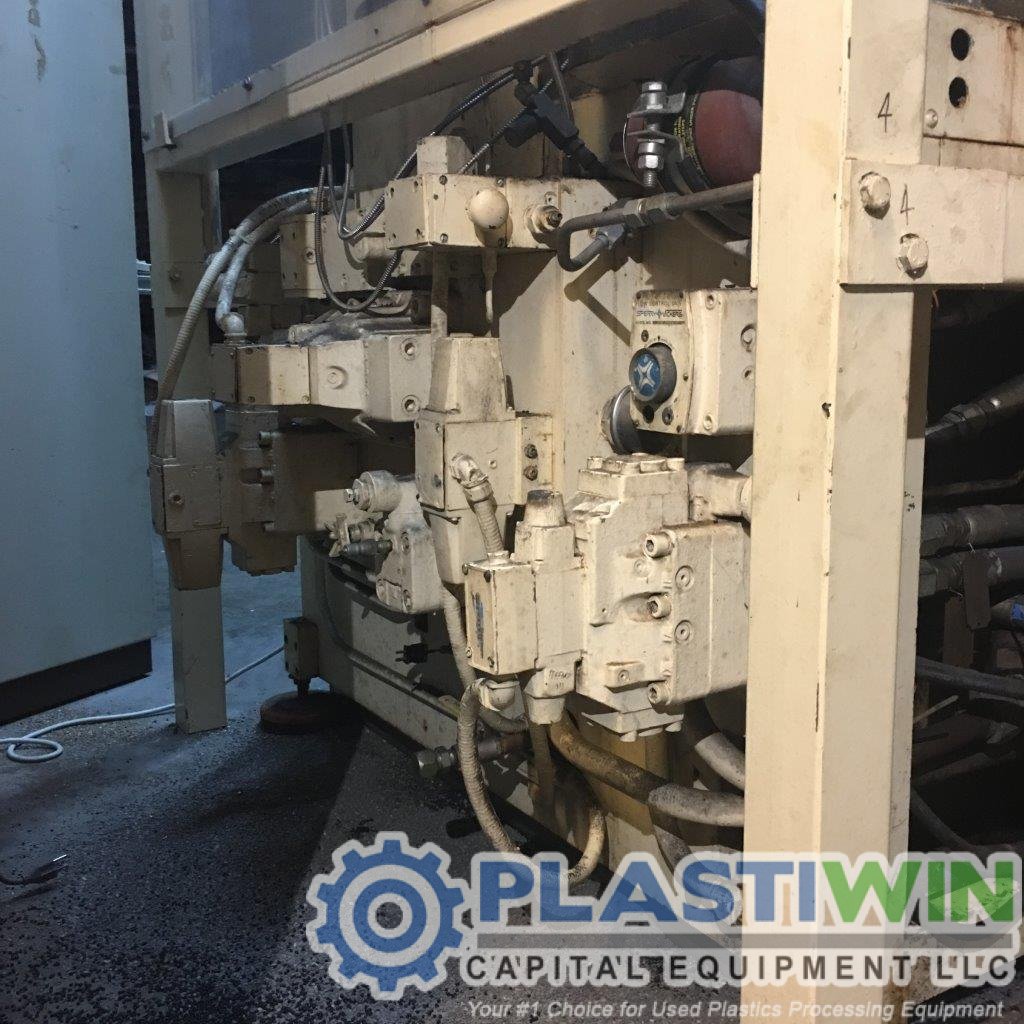

Jomar 65 Injection Blow Molding Machine - 1

* Brand: Jomar

* Year of Mfg: August 1976 - Rebuilt and idle since 1994

* Platen Size: 17"deep X 26" width maximum mold size

* Extruder Size: 2" diameter screw 30:1 LxD vertical screw

* Head Size: preform: 23"W x 11"D x 3 1/2" H blow:16"W x 11"D x 2"H

* Clamp Force: Pre-form head 52 tons, Blow head- 17 tons

* Daylight: 13.75" table platen to press head with cylinders in retracted position

* Controller: Allen Bradley PLC5/11 processor

* Number of Heads: 1 preform station, 1 blow station

* Recent Upgrades: 19994

* Products Made: Steering bellows for VW car

* Hours: 80 since rebuilt in 1994

* Voltage: 480 VAC, 40HP 3 Phase Motor

* General Condition: Good

* Machine was operational when taken out of service

* Materials ran: Santoprene 101-87 thermoplasic rubber

Auxilliary equipment Included with Machine:

* 2 each VW steering bellow molds

* 1 each 2-zone oil heater Sterlco Model F6026-DX 24kw per zone, 3phase 62A, 480v

* 1 each 1-zone oil heater Advantage Model 760-920H-21A1-x, 3phase 30A, 480v

* 1 each 3-zone water heater/cooler Sterlco Model M8332-AX 9Kw per zone

* 1 each Desiccant dryer Thoresen McCosh Model D100T with hopper and diffuser system

* 1 each transfer hopper Plastic Process HL-1 500# per hour

* 1 aa water cooling tower, with 4" stainless steel piping and stainless steel valves

* 1 each water circulating system with 500 gallon reservoir with level and temperature controls

* 2 each 200 GPM @ 50ft head cast iron centrifical pumps with 5HP TEFC motors

Additional Upgrades and Other Options:

* 1 each stainless steel hydraulic oil cooler Thermal Transfer R-1003-A4T-SS

* 1 each brass Y-strainer Keckley and new 1" hard copper plumbing to hydraulic oil cooler

* 1 each hydraulic oil temperature control valve (brass) Sterlco 941

* 1 each Allen Bradley PLC-5 controller

* 1 each Allen Bradley 6200 series programming software on Dell PC

* 1 each Remote Control cabinet Emcor 86"H 26'W x 25.5"D for operator safety

* 1 each separate controls and instrument wiring conduits to control cabinet

* 6 each Heat zone process controllers Athena XT-18 series 4-20ma

* 6 each Solid state relays Athena 39z-48 control of heating elements 4-20ma

* 30 each 30mm push buttons and lamps GE CR104 series

* 2 each Plexiglas vertical gates on front and rear to aid in machine access

* 2 each Plexiglas removable side covers to aid in machine access

* 1 each 1 1/4" return filter 10 micron with dirty filter pressure gauge

* 1 each hydraulic tank oil filler moved to front of machine away from plastifier

* 1 each hydraulic oil temperature gauge 6" diameter on machine front

* 1 each hydraulic oil level sight gauge Lube Devices 8" on machine front

* 2 each front and rear cross bars on machine frame, for lifting support

* 8 each replaced table to frame hold down bolts

* 1 each repaired stress cracks on frame at bolt center line preform cylinder per Jomar procedure

* 1 each added water control valves and stainless steel hoses for plastifier/hopper cooling control

* 1 each replaced all hydraulic hoses with 6 wire 100R12 4000 PSI rated hoses safety and lifespan

* 2 each replaced air regulators for 1st and 2nd blow station

* 2 each replaced electric motor to pump couplings Magnaloy

* 5 each replaced rod and piston seals on all cylinders in 1994

* 1 each Lot of assembly and wiring drawings and AutoCAD files

* 1 each Parts manuals and purchase order records for upgrades